Real Savings

See how real business owners continue saving, long after the upgrades are done.

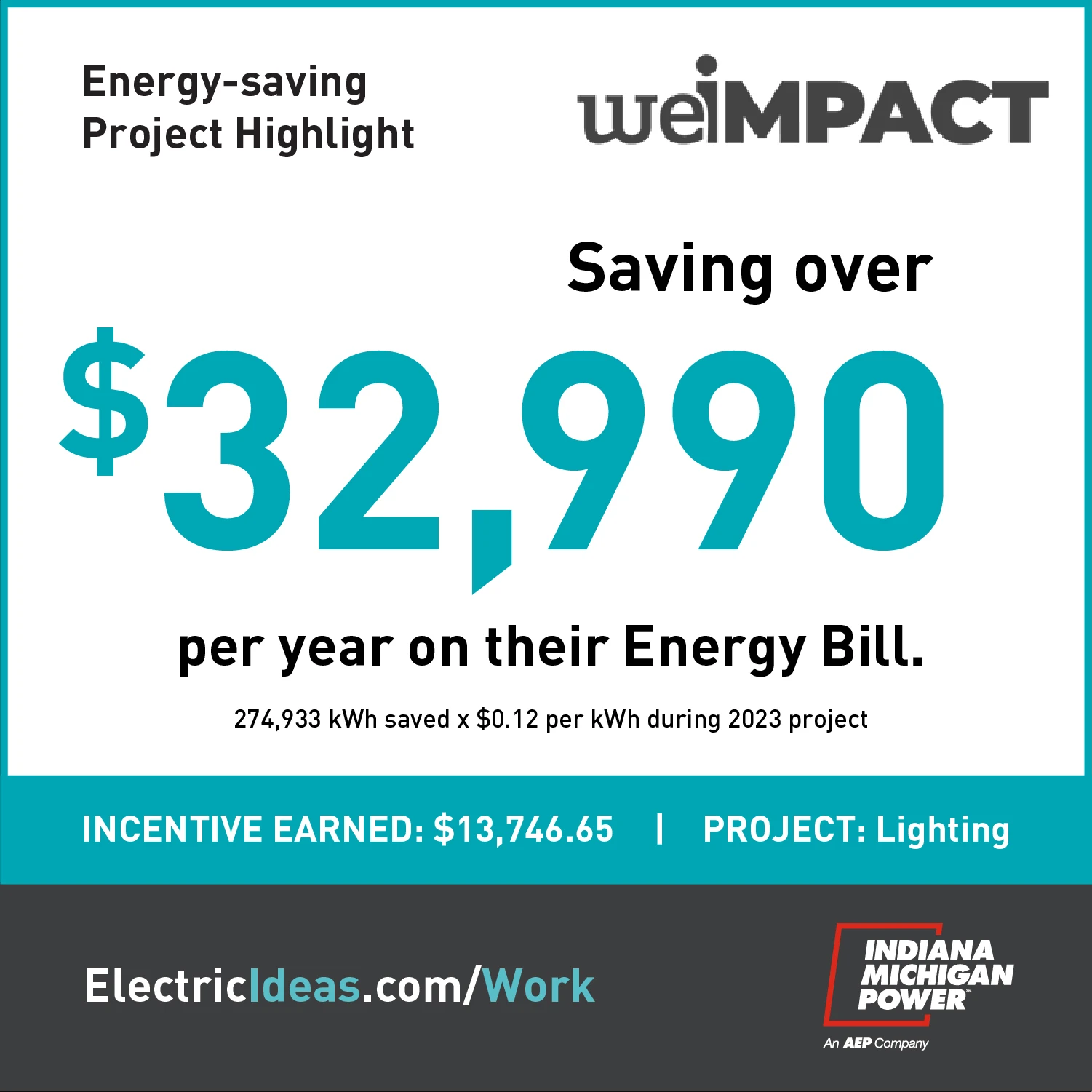

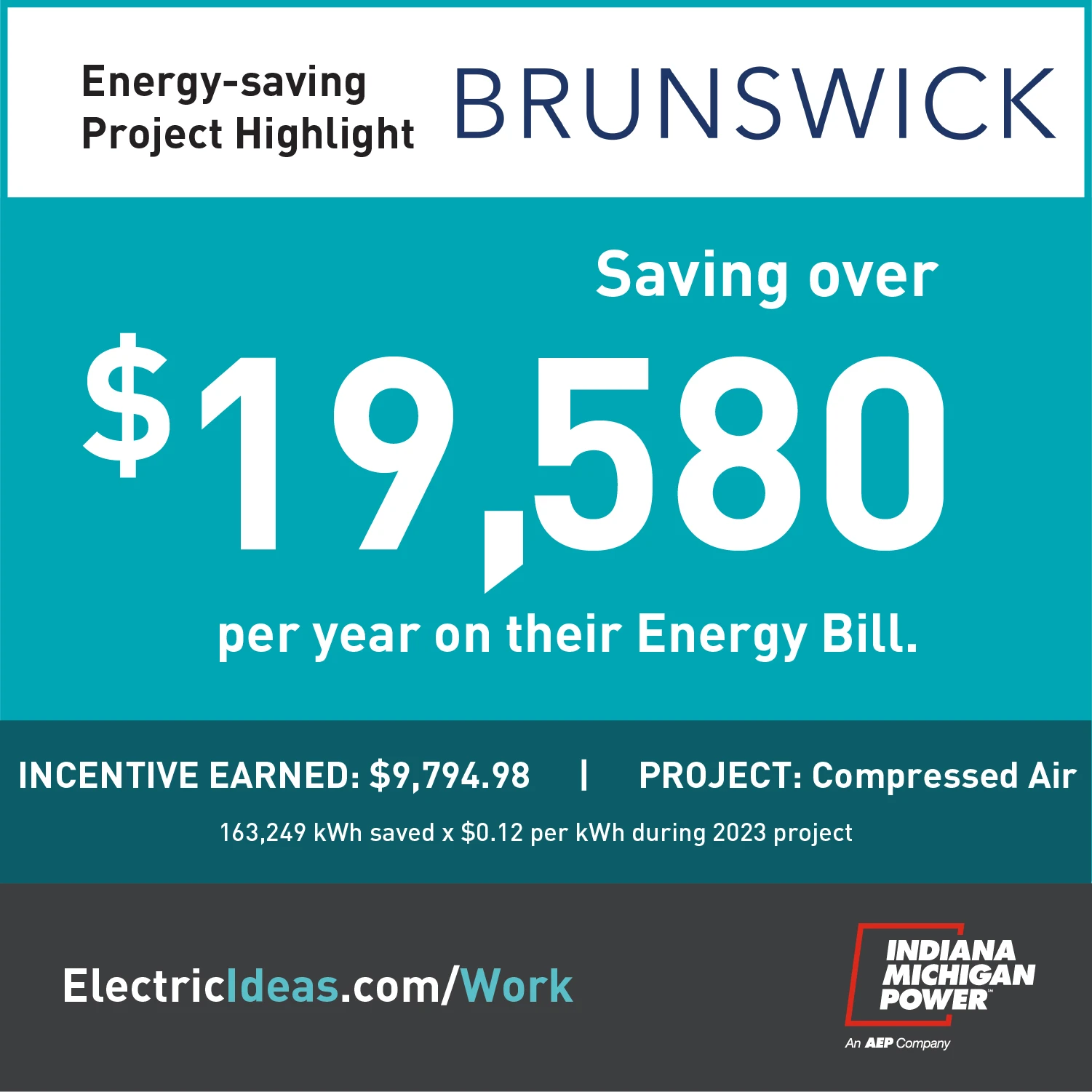

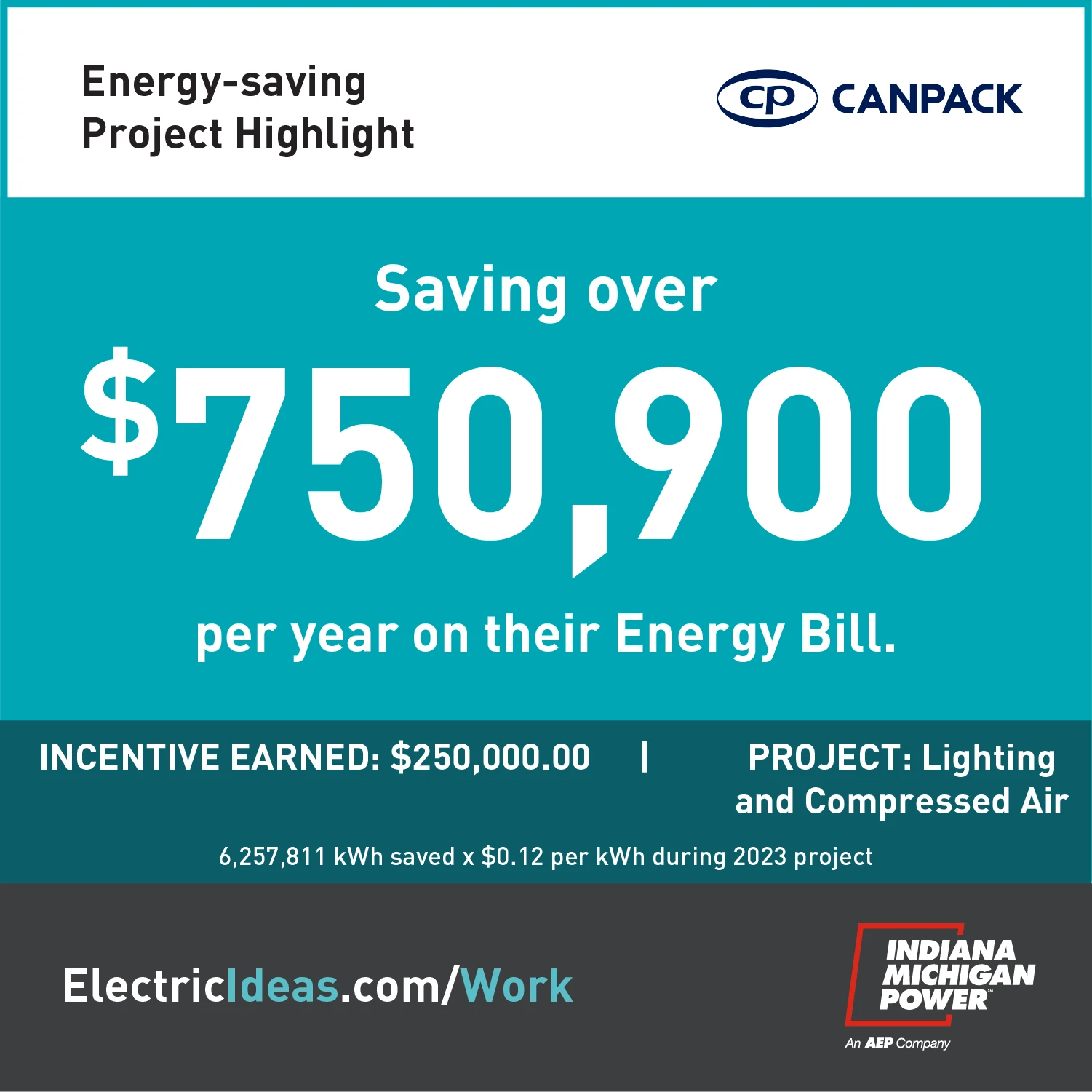

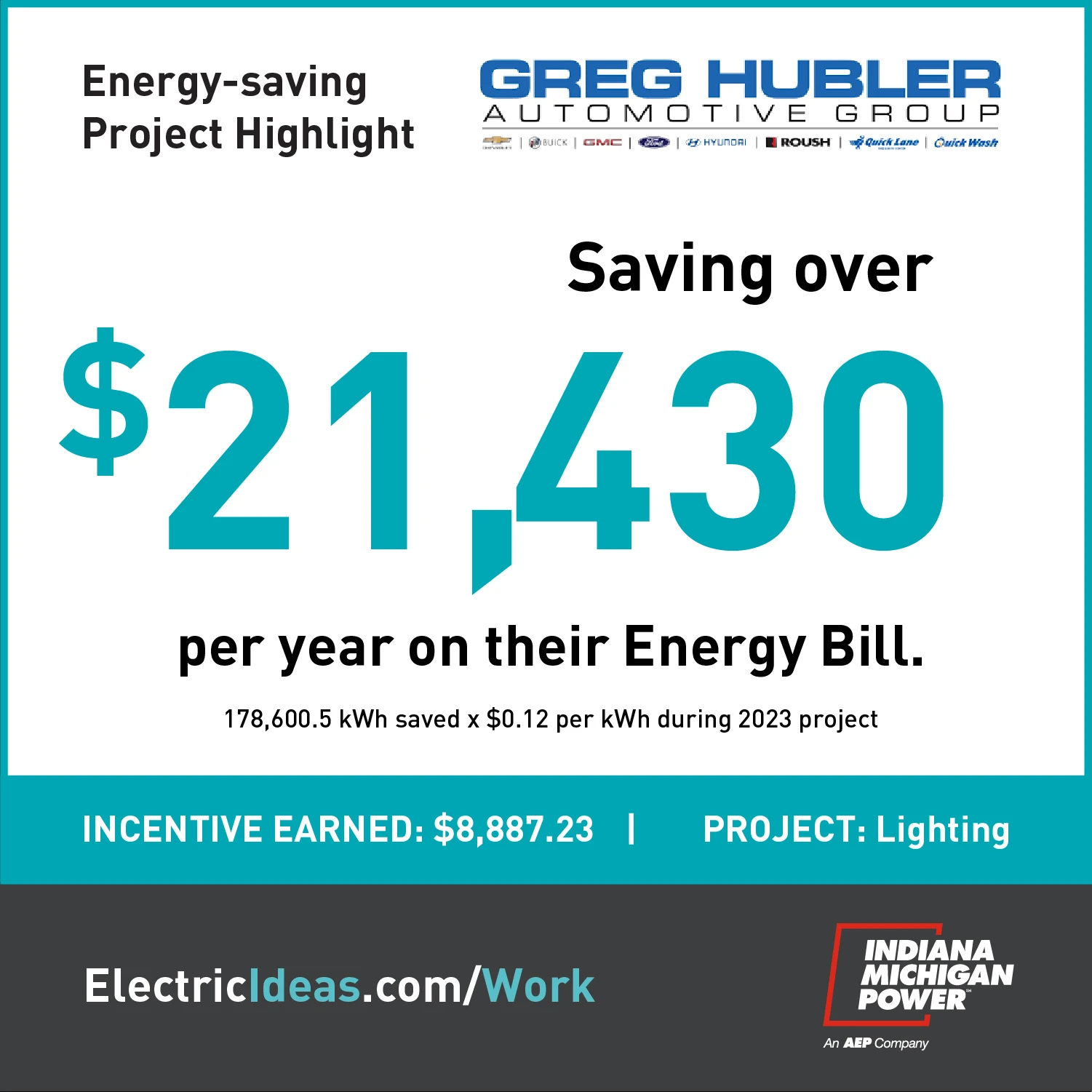

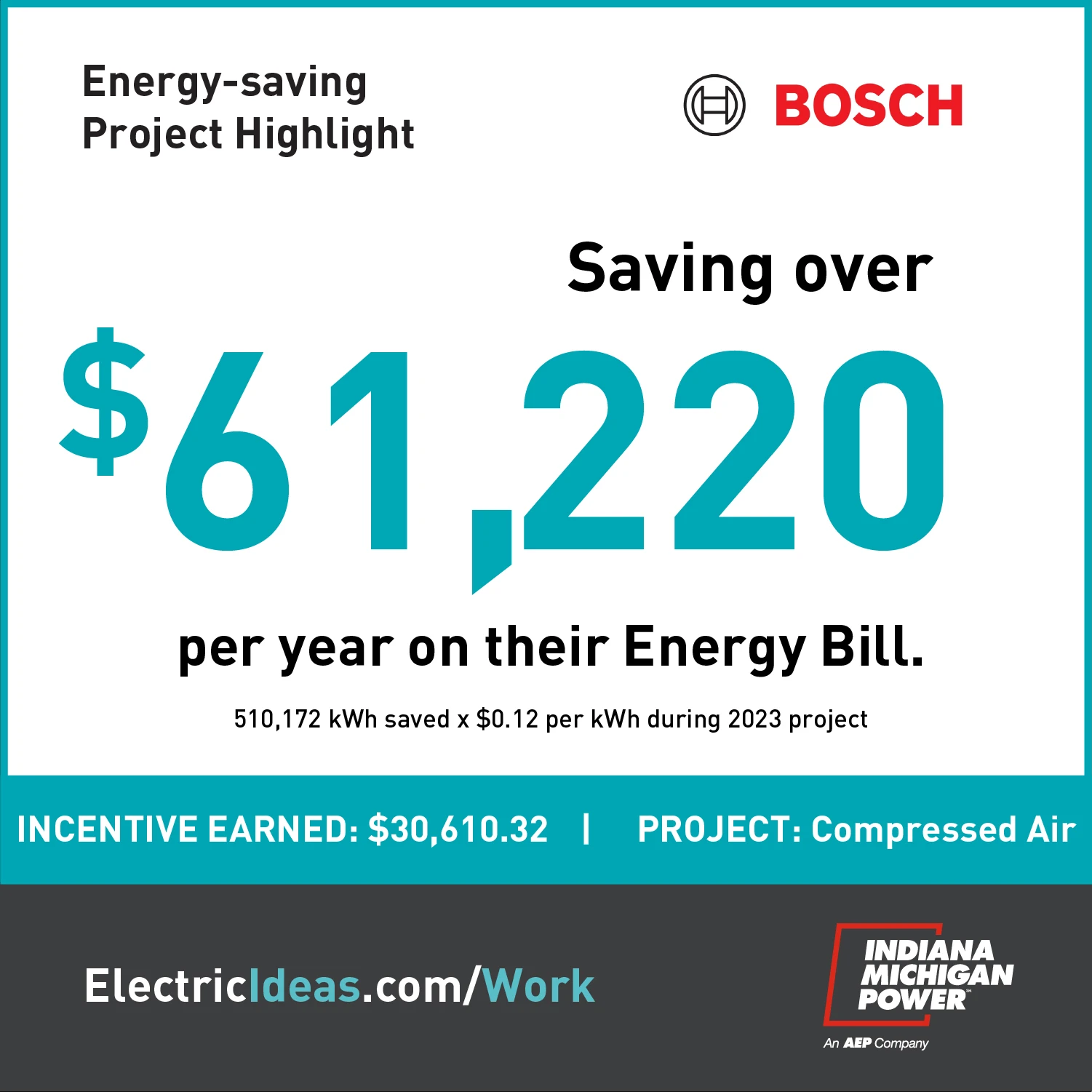

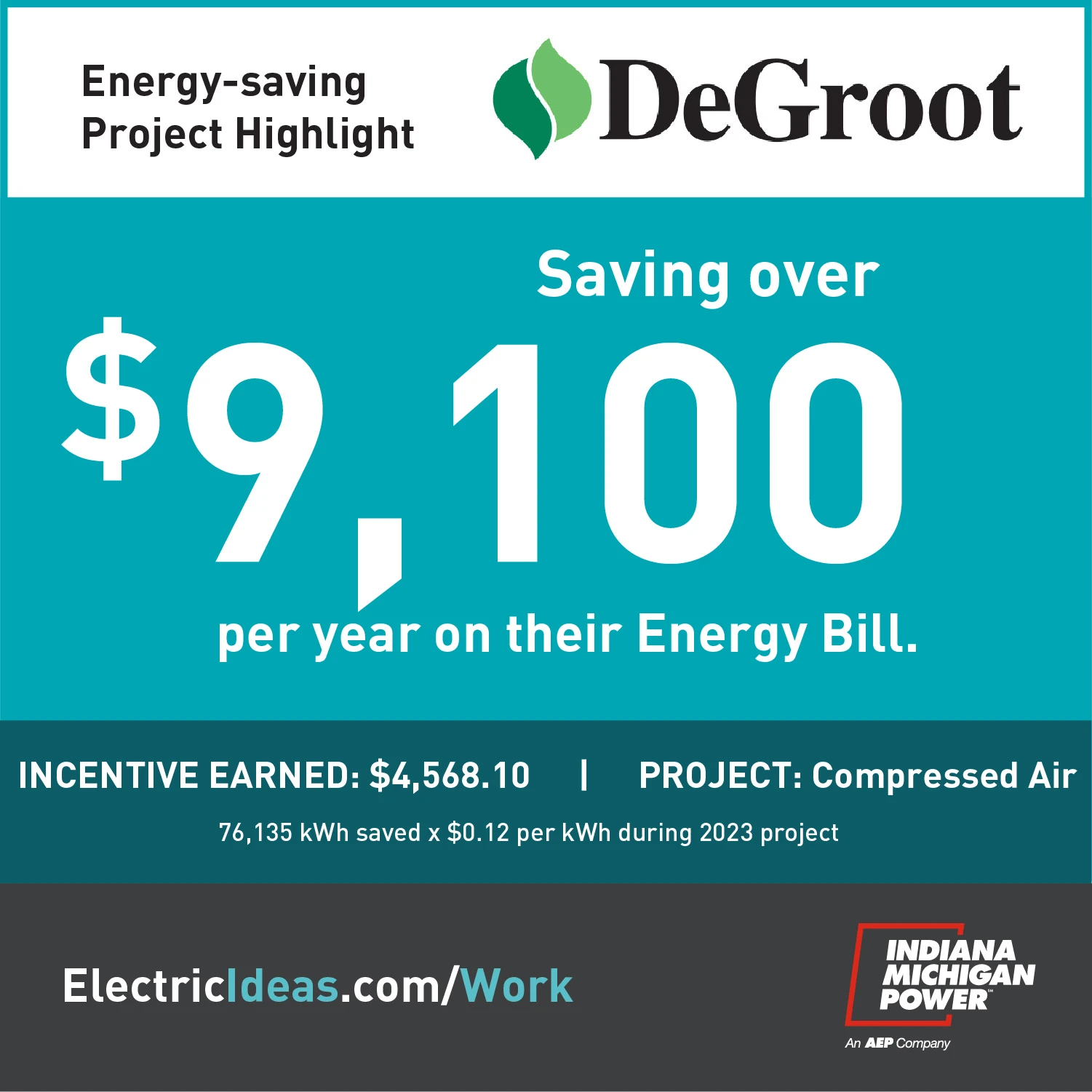

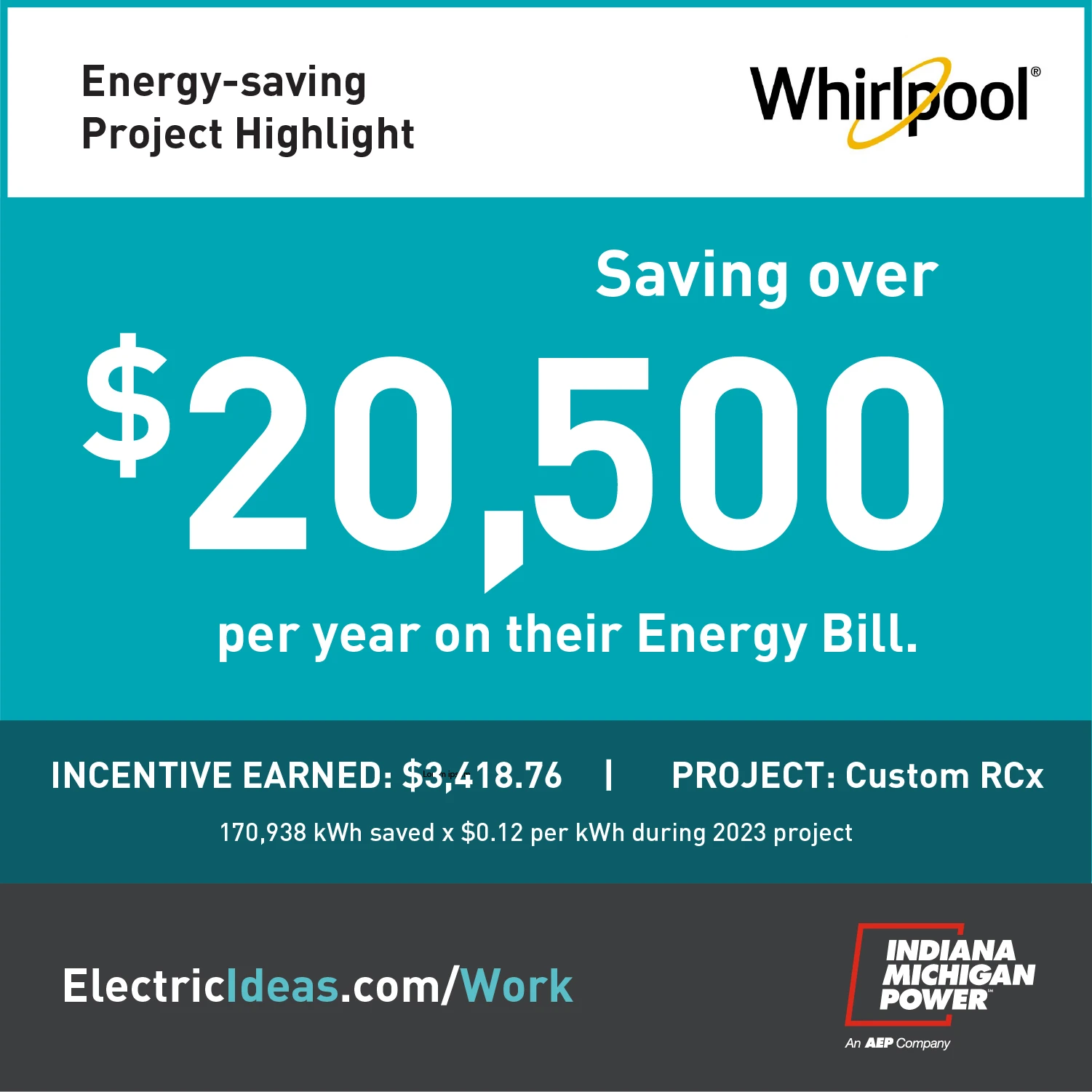

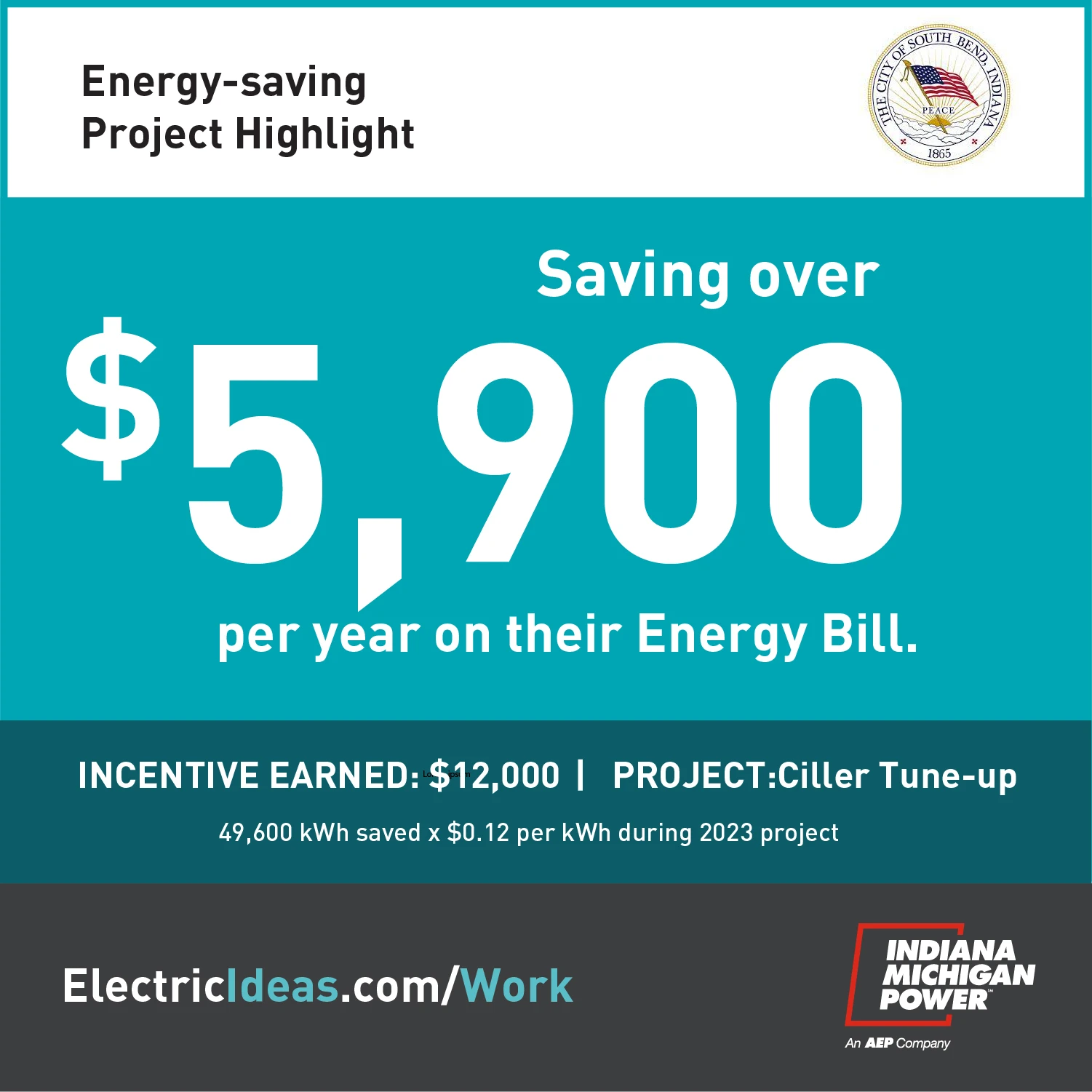

Case Study Highlights

Long Form Case Studies

GAST Manufacturing, Inc. specializes in offering cost effective air-moving solutions for a wide variety of industries, including healthcare, environmental cleanup applications, and industrial manufacturing. To help save on overall energy costs, GAST met with Indiana Michigan Power (I&M) to discuss their energy efficiency opportunities. Through conversation, I&M recommended a Find & Fix compressed air leak study and repair. This two-step study first identifies where air leaks are present, then repairs them to minimize energy waste.

Working with one of our participating trade allies, the study identified over 190 leaks, of which more than 75% were able to be immediately repaired. The result, over 779,000 kWh saved annually by repairing the compressed air leaks. That’s over $93,500 saved each year! Learn more

Project Results and Stats

Industry:

Manufacturing

Product:

Quality air-moving solutions

Time to install:

Two Weeks

Estimated annual energy savings:

Over 779,000 kWh

Estimated annual cost savings:

$93,500

Project payback:

4 months

Rebate amount:

$22,500

Global manufacturing leader JVIS and their sister company, Nova, met with Indiana Michigan Power (I&M) to discuss their energy efficiency opportunities after working with the state of Michigan on similar energy waste reduction initiatives. Upon learning that similar rebates were available through I&M, they implemented multiple energy-saving upgrades, including barrel insulation for injection molding projects. JVIS worked closely with a trade ally to measure their machines. Within a month, custom barrel insulation wraps were installed and saving JVIS energy and money.

The barrel insulation is estimated to reduce the facility’s annual energy by over 2,070,000 kWh, saving JVIS and Nova over $225,000 per year. Since completing the project, JVIS and Nova are planning to partner with I&M to make other energy-efficient upgrades. Learn more

Project Results and Stats

Industry:

Manufacturing

Product:

Barrel insulation for injection molding

Time to install:

One month

Estimated annual energy savings:

Over 2,070,000 kWh

Estimated annual cost savings:

Over $225,000

Project payback:

One year

Rebate amount:

$128,690

The Opportunity

Lippert Components manufactures and supplies highly engineered, high-quality components to the recreational vehicle, marine, automotive and building products industries. With over 90 facilities in 17 states, Canada and worldwide, Lippert Components has made the choice to prioritize social impact initiatives.

To help save on energy costs, Lippert Components got in touch with Indiana Michigan Power (I&M) to discuss their energy efficiency opportunities.

The Project

It all started with Lippert Component’s initiative to identify high-impact, cost-saving projects! One of those projects proposed was updating existing lighting to energy-efficient LED tubes throughout the warehouse.

Working with I&M, Lippert was able to upgrade the inefficient lighting to new, rebate-eligible LEDs. Based on the savings achieved from this project and the end result, Lippert Components is looking for additional ways to utilize commercial rebate programs to make energy-efficient upgrades in other facilities. Learn more

“Working with the I&M rebate programs enabled us to provide brighter, safer work spaces for our teams, while reducing the maintenance needed. The program provided a favorable return on investment and we’re excited to duplicate this project throughout our other facilities.”

— Richard Wallock, Facility Manager, Lippert Components Plant 50-W

Project Results and Stats

The new lighting is estimated to reduce the facility’s annual energy use by over 1,000,000 kWh, saving Lippert Components over $110,000 a year.

Since completing the initial project, Lippert Components worked with I&M to upgrade another project and is looking to complete lighting retrofits at other facilities in the near future.

Industry:

Manufacturing

Product:

Lighting

Estimated annual energy savings:

Over 1,000,000 kWh

Estimated annual cost savings:

Over $110,000 a year

Our program provides training, motivation and engineering support to move your company culture toward sustainability.

Energy Management Tools allow you to manage, track and optimize your company’s energy use.